Semiconductor DTFS

Semiconductor DTFS

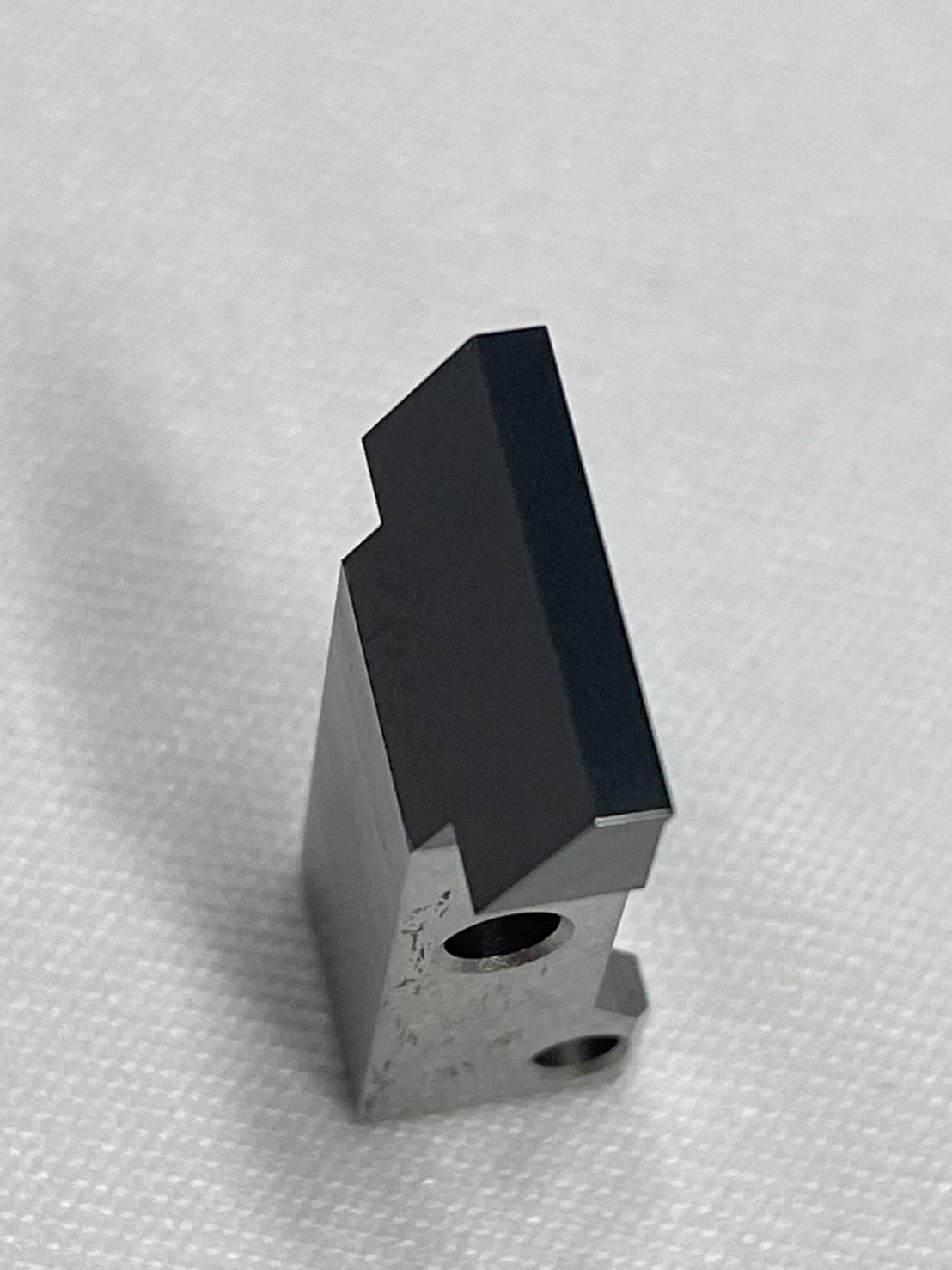

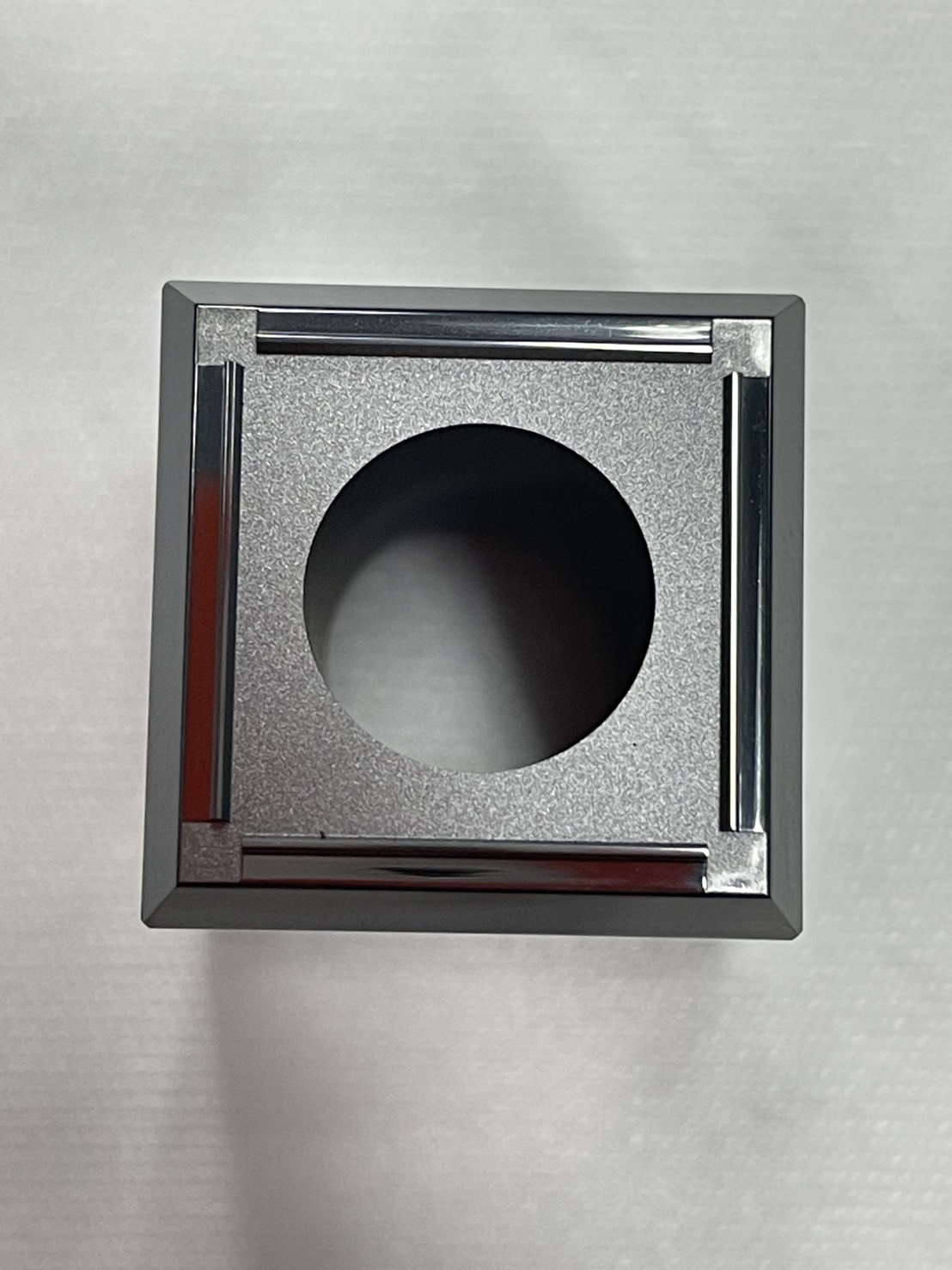

In the manufacturing of IC packages, trim and form tools are often faced with metal alloying problem. The lead frames are often coated with Lead, Tin or palladium. These soft material often alloy or diffuse onto the forming tools after a prolong period of production.

To tackle this problem, DLC is often applied on these tooling to prolong the service life of the tools before they are taken down for cleaning.

PDLC with its superior hardness compared to normal DLC offers higher wear resistance. Therefore, it is possible to extend service life further for steel punches as well as tungsten carbide punches.

The amorphous structure of PDLC offers lower sticking possibilities of plating on the punch surface and die sets cleaning downtime can be critically reduced.

| Film Properties | PDLC | Typical DLC (a-C:H) |

| Diamond bonding structure | Approx. 85% | Approx. 25% |

| Density (g/cubic cm) | 3.8 | 2 |

| Max Hardness (Gpa) | Approx. 40 | Approx. 15 |

| Coefficient of Friction | Approx. 0.1 | Approx. 0.14 |

| Coating Temperature (°C) | < 100 | Approx. 200 |

| Working Temperature (°C) | 350 | 350 |

| Typical Thickness (ηm) | 1 to 2 | 1 to 2 |